| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Mullite Refractory Bricks |

|---|---|

| Brand Name: | FS |

| Model Number: | FS-8746 |

| Certification: | SGS,CE |

| Place of Origin: | China |

| MOQ: | MOQ:100PCS |

| Price: | 900USD/ton |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 1000ton/month |

| Delivery Time: | 15 working days |

| Packaging Details: | tray,PE |

| Color: | Yellow |

| Density: | 3.5 g/cm3 |

| Size: | 230*114*65mm |

| Application: | kiln |

| chemical composition: | Mgo |

| AL2O3 % (≥): | 55 |

| Refractoriness under load, 0.2MPa, °C (≥): | 1450 |

| Permanent linear Change, %: | +0.1 -0.3 |

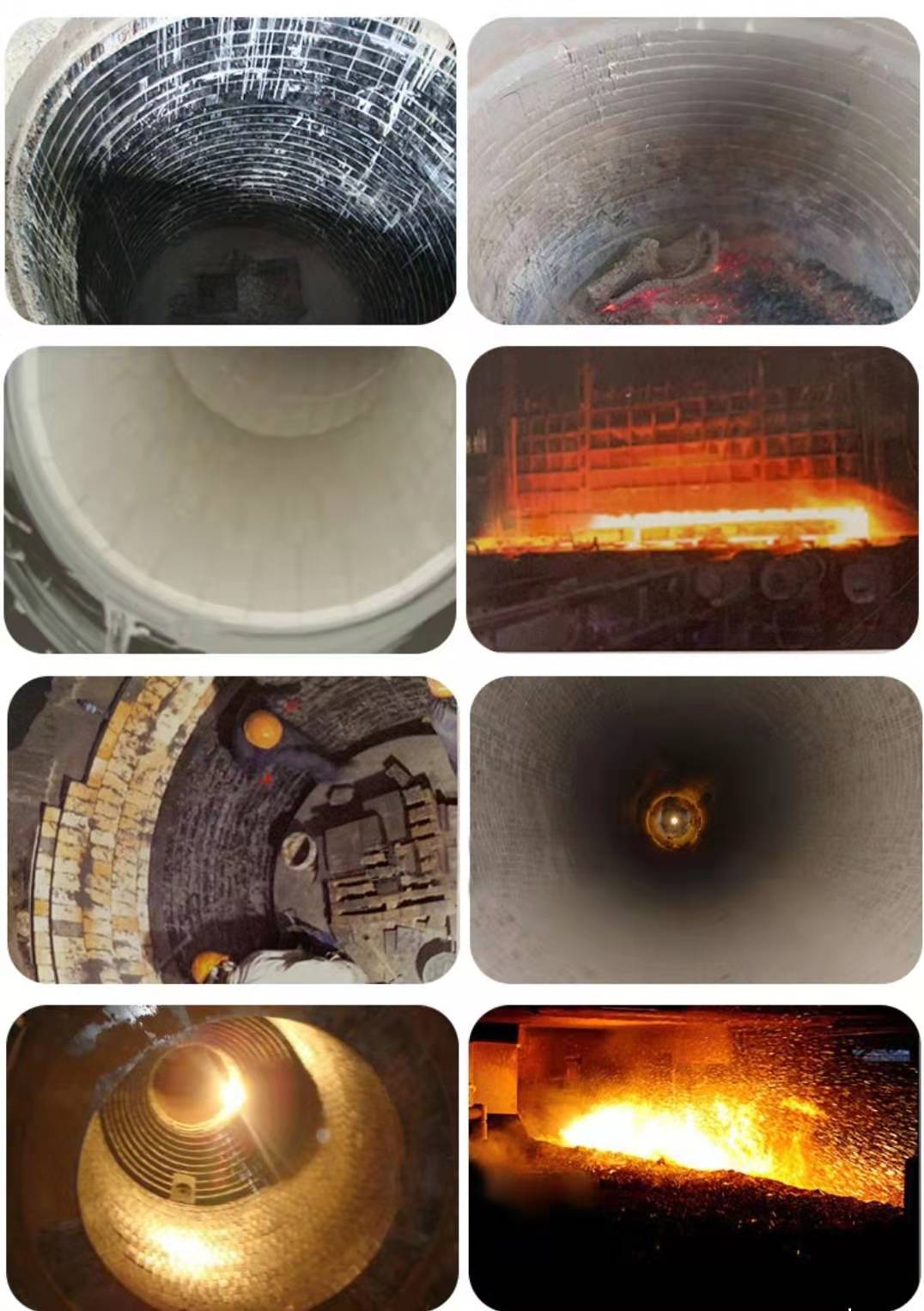

FS arched brick fireplace is an alumina-silicate refractory material in which the Al2O3 content is more than 55%, and is calcined from a high-content alumina raw material such as a silicone raw material or a bauxite. High heat resistance and high temperature resistance at 1770 ° C and above. Has good slag resistance, mainly used in the masonry of steelmaking electric furnace, glass furnace, cement rotary furnace and so on.

Characteristics of Refractory Brick for Kiln Furnace

1.Refractoriness:

More refractory than refractory clay bricks and semi-silica bricks, up to 1750-1790C, belonging to high-grade refractory materials.

2. Load softening temperature:

Since the high aluminum has a high Al2O3 content, a low impurity content, and a low formation of the molten glass body, the fire-resistant softening temperature is higher than that of the refractory clay brick. However, since the mullite crystal has not yet formed a network structure, the load softening temperature is lower than the load softening temperature of the silica brick.

3. Slag resistance:

High Al2O3 has high Al2O3 content, close to neutral refractory material, and can resist the erosion of acid slag and alkali slag. Because it contains SiO2, the resistance to alkali slag is less than acid resistance.

Physical And Chemical Indicators For fire brick for heating furnace

| Item/Grade | Fire clay brick | High alumina brick | |||||||

| SK-35 | SK-38 | SK-42 | SK-45 | SK-55 | SK-65 | SK-75 | SK-85 | ||

| AL2O3 % (≥) | 35 | 38 | 42 | 45 | 55 | 65 | 75 | 85 | |

| Refractoriness °C (≥) | 1680 | 1730 | 1750 | 1760 | 1770 | 1790 | 1790 | 1850 | |

Refractoriness under load, 0.2MPa, °C (≥) | 1350 | 1370 | 1400 | 1420 | 1450 | 1500 | 1550 | 1600 | |

Permanent linear Change, % | 1500°C ,2h | 0.1-0.4 | 0.1-0.4 | 0.1-0.4 | 0.1-0.4 | ||||

| 1400 °C,2h | +0.1 -0.3 | +0.1 -0.3 | |||||||

| 1350 °C,2h | +0.2 -0.4 | +0.1 -0.3 | |||||||

| Apparent porosity % (≤) | 24 | 22 | 20 | 20 | 22 | 23 | 23 | 23 | |

| Cold crushing strength ,MPa (≥) | 25 | 30 | 35 | 40 | 45 | 50 | 60 | 70 | |

Application of Refractory Brick for Kiln Furnace

1. Iron&steel making industry:

fire clay brick for refining furnace fire clay brick for refining furnace,Blast furnace,hot blast furnace(stove),pellet shaft furnace,hot metal ladle,steel ladle, tundish,heating furnace,soaking pit furnace,heat treatment furnace,refining furnace,reheating furnace,metal mixter furnace,annealing furnace, cupola furnace,electric arc furnace,induction furnace,AOD furnace,VOD furnace,etc thermal technology equipment.

2. Non-ferrous Metal industry:

Smelting furnace,refining furnace,reverberatory furnace,converter furnace.

3. Building materials industry:

Cement kiln,glass kiln,ceramic kiln,lime kilns,kiln car,tunnel kiln

4. Energy & Incineration:Coke oven,general boiler,power,generation,boiler,circulating fluidized bed boiler,electric furnace,carbon rosating furnace,waste incinerators.

5. Others:Petrochemical industry furnace.

|