| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Racking Roll Forming Machine |

|---|---|

| Brand Name: | BMS |

| Model Number: | Shelf |

| Certification: | SGS,CE,ISO9001 |

| Place of Origin: | Xiamen,China |

| MOQ: | 1 set |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 35set per month |

| Delivery Time: | 50days |

| Packaging Details: | Naked machine covered with plastic film, fixed by steel rope. |

| Control system: | PLC |

| Material: | Cold Rolled Sheet |

| Speed: | 14m/min-16m/min |

| Material Thickness: | 1.5-2.0 |

| Cutting type: | Hydraulic cutting |

| Roller material: | GCr15,CNC lathes,Heat Treatment,hard Chrome Coated with thickness 0.04mm,surface with mirror treatment |

| Shafts Diameter: | ф75mm,Precision machined |

| Main Motor: | Polaroid brand |

| Company Info. |

| Xiamen BMS Group |

| View Contact Details |

| Product List |

Cold Rolled Sheet Shelf Heavy Column Machine 14m/min-16m/min Speed with PLC

Our factory has more than 20 years of experience in roll forming machines. We have our own design team and R & D team, producing different types of roll forming machines with automated production and simple operation. 24-hour online technical support, local engineer technical support, global after-sales service.

Working flow

Decoiler----Feeding+Leveling(upper three rollers, down four rollers)----Roll forming----Hydraulic Cutting----PLC----Output table

Automatic Uncoiler with press arm and control box

Tensioning method: hydraulic tensioning

Coil width: 600mm

Uses: used to support the steel coil and unroll the coil in a

rotatable manner.

Load capacity: 5T

Inner diameter: 508 ± 30mm

Emergency stop device

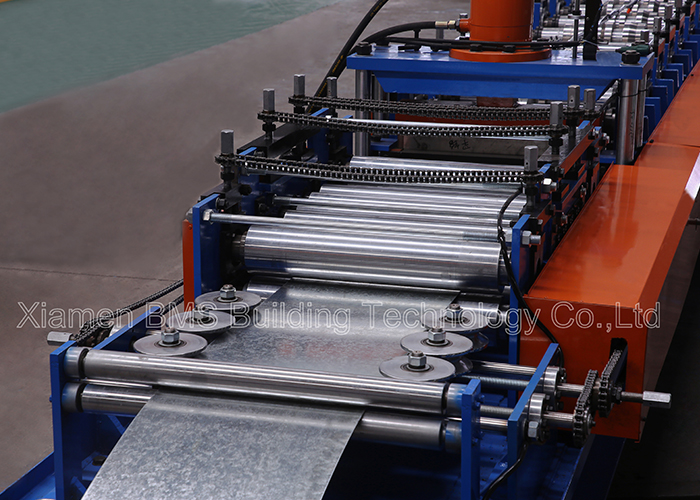

Main forming machine

The material of the main shaft: 45 # steel, adjusted

Hydraulic system and computer control cabinet

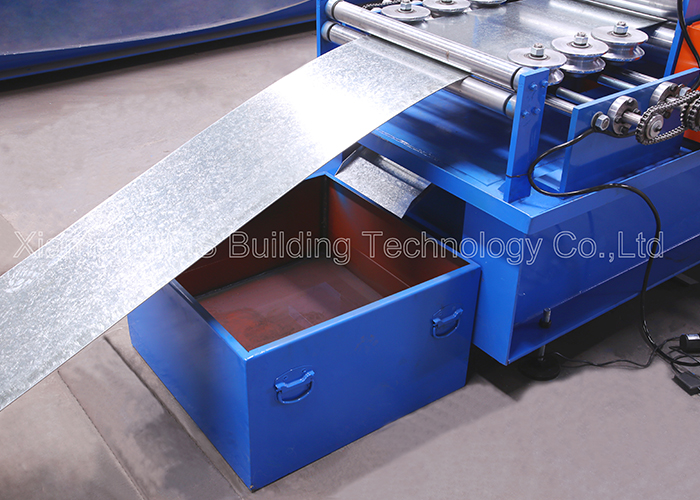

Hydraulic oil: 40 #

The hydraulic oil enters the hydraulic oil tank, and the pump

drives the cutting machine to start cutting.

Encoder: Automatically adjust the cutting method, number of cuts,

and count automatically, without manual counting.

PLC: European brands ---- Siemens, Schneider

Cutting: It uses the hydraulic drive and automatic positioning to

size and cut the target product.

Cutting blade material: Cr12MoV, quenched, hardness reaches 58-60 °

Main power: 380V / 50HZ / 3PH

Product parameters:

| No. | Main parameter name | Feature |

| 1 | Forming station | 30 station |

| 2 | Roller material | High-grade GCr15 material, heat treated |

| 3 | Heat treatment | All roller dies have been heat-treated to reach HRC = 58-60° |

| 4 | Spindle material | 45 # steel, quenched and tempered |

| 5 | Memorial arch structure | A3 board integral archway 30mm thick |

| 6 | Transmission way | Chain drive, all chain sprockets are processed by high frequency |

| 7 | Transmission power | 15kw national standard copper core motor, JZQ350 gear reducer |

| 8 | Frame structure | H400 type steel by welding |

| 9 | Cut off method | Hydraulic automatic mold cutting |

|