| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Metal Slitting Line |

|---|---|

| Brand Name: | YBT |

| Model Number: | YB952608 |

| Certification: | CE ISO SGS |

| Place of Origin: | China |

| MOQ: | 1 Set |

| Price: | Negotiation |

| Payment Terms: | T/T |

| Supply Ability: | 2set |

| Delivery Time: | 60-90 days |

| Packaging Details: | Standard export packing with each machine tied and protected in container |

| Product Name: | High Speed Slitting Machines |

| Line speed: | 0-80m/min |

| Warranty: | 1 Year |

| Capacity: | 360 KW |

| Power: | 380V/50Hz/3Ph(Customized) |

| Control system: | PLC control |

| Model No. | RS 1.0-6.0 | RS 2.0-8.0 | RS 3.0-10.0 | |

| Coil Material | CR Coils , HR Coils, S.S Steel Coils, GI Coils , AL Coils, Copper Coils Picking Oil Coils | |||

| Coil Thickness | 1.0~6.0mm | 2.0~8.0mm | 3.0~10.0mm | |

| Line Speed | 0~110m/min | 0~50/80m/min | 0-30/50m/min | |

| Coil Weight | ≤30T(35T) | ≤30T(35T) | ≤30T(35T) | |

| Coil I.D | Φ508,φ610,φ760mm | Φ508,φ610,φ760mm | φ508,φ610,φ760mm | |

| Coil O.D | ≤φ2200mm | ≤φ2200mm | ≤φ2200mm | |

| Strip Width | ≥30mm | ≥50mm | ≥70mm | |

| Number of Strip | 4~15 | 5~20 | 5~18 | |

| Slitting Accuracy | ±0.3mm | ±0.3mm | ±0.3mm | |

| Blade shaft | Ф260mm | Ф280mm | Ф300mm | |

| Electrical Control System | PLC Automatic control | PLC Automatic control | PLC Automatic control | |

Metal Slitting Line Main Technical Specifications

| COIL/ROLL DETAILS | Material | HR, CR, SS, GI, PPGI, Copper |

| Tensile Strength | δb≤600Mpa,δS≤360Mpa | |

| Coil/Roll thickness | 1-10mm | |

| Steel Coil/Roll width | 500-2200(Max) | |

| Coil/Roll I.D | Φ500-760 mm | |

| Coil/Roll O.D | Φ2000mm(Max) | |

| Steel Coil/Roll Weight | 35T(Max) | |

Slitter parameters | knife pivot diameter | Ф220 mm |

| Knife pivot material | 40Cr | |

| Blades specification | Φ220mmXφ360mmX20mm | |

| Blade material | 6CrW2Si | |

| Max slit quantity | 4 pcs (4mm) 20 pcs(1mm) | |

| Width precision | ≤±0.05mm | |

Other parameters | Power | 380V/50Hz/3Ph(Customized) |

| Line speed | 0-80m/min | |

| Capacity | 360 KW | |

| Whole line Dimension | 45m(L)X10m(W) | |

| Line direction | From right to left(Face to machine) | |

| Machine color | Blue |

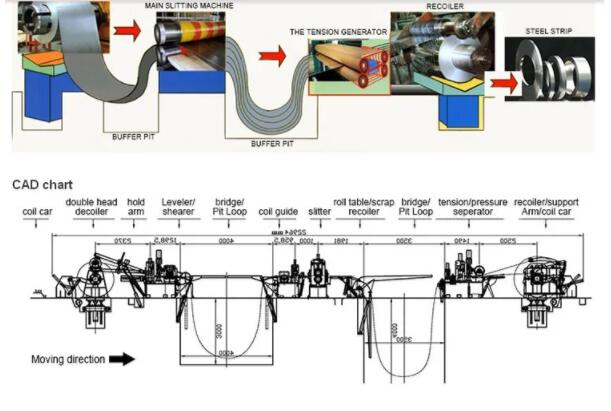

Process Flow:

Our Services

1) We will send the engineer for the installation and training your workers how to operate this machine in correct way.

2) Warranty Team

One year quality guarantee, life guarantee repair. Within quality guarantee period, except for failures caused by human error, repair parts will be provided for free. After the quality guarantee period, only charge the cost of the spare parts.

3) We supply the pre-sell and after-sell service.

pre-sell service: workshop design, and production output design

after-sell service: installation and training, and the skilled engineer for working.

4) We can also sent the engineer working for you serval months or 1 year. The engineer will help you to improve the output, reduce the waste and decrease the cost.

5) We supply the pre-sell service-Design for whole project for stainless steel pipe making/ carbon steel pipe making.

6) We will be responsible for the loading and shipping

|