| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Kenwei Multihead Weigher |

|---|---|

| Brand Name: | Kenwei |

| Model Number: | JW-A14 |

| Certification: | CE,SGS,OIML |

| Place of Origin: | Guangdong,China |

| MOQ: | 1 set |

| Price: | USD4100-4400 |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 800 set per/year |

| Delivery Time: | 20-45 working day |

| Packaging Details: | Wooden Crate Package |

| Identify Code: | A14-1-3 |

| Weighing Range: | 10-1500g |

| Accuracy: | X(0.5) |

| Max Speed: | 100P/M |

| Hopper Volume: | 1.6L |

| Control Panel: | 7”Touch Screen |

| Options: | Dimple Plate/Timing Hopper/Printer/Reject Device |

| Power Requirement: | 220V/1500W/ 50/60Hz /12A |

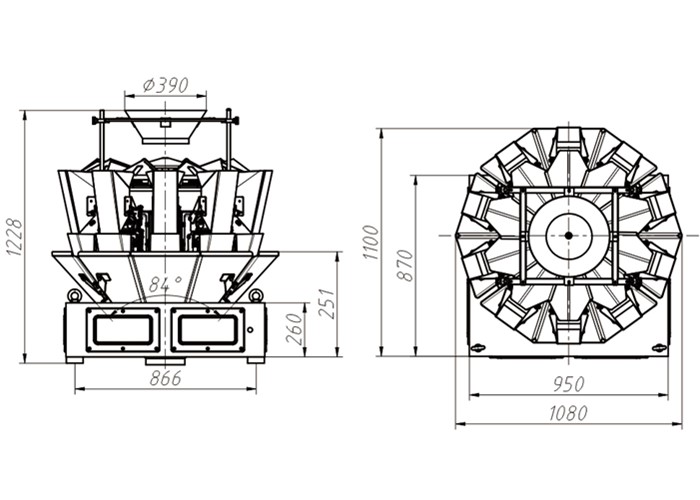

| Packing Dimension(mm): | 1700(L)X1110(W)X1265(H) |

| Gross Weight: | 490kg |

High accuracy Standard no-spring weigher For Weighing food more effectively

The High accuracy Standard no-spring weigher stable operation,

superior cost performance, 10 years selling model.

Rust-proof, dust-proof and non-spring hopper design, more protect

food safety. easy to use.Can meet 1 different volume of hopper

volume selection

Features

1. Linear amplitude can be adjusted independently;

2. No products auto pause function can improve weighing stability

and accuracy;

3. Many languages available for global markets;

4. 100 programs capacity can meet various weighing requirements and

user-friendly help menu contributes to easy operation;

5. Adopt high precision and high accurate loadcell of famous brand,

resolution is improved up to 2 decimal;

6. Program recovery function can reduce operation failures and

support multi-segment weight calibration.

Mechanical character

1.No-spring hopper with patent, economical and practical,

cost-effective;

2.Use no-spring hopper to ensure food safety more effectively;

3.Mold making process and uniform design standards contribute to

better interchangeability for spare parts;

4. Weighing type for material detection is available, which can

make accurate control of feeding time & material thickness and

ensure weighing accuracy;

5. Aluminum thickened middle standing enhances the strength of the

machine, making the time for stabilizing hoppers much shorter.

Technical specification

| Model | JW-A10 | JW-A14 |

| Identify Code | A10-1-3 | A14-1-3 |

| Weighing Range | 10-1000g | 10-1500g |

| Accuracy | X(0.5) | X(0.5) |

| Max Speed | 60P/M | 100P/M |

| Hopper Volume | 1.6L | |

| Control Panel | 7” Touch Screen | |

| Options | Dimple Plate/Timing Hopper/Printer/Reject Device | |

| Driving System | Step Motor | |

| Power Requirement | 220V/1000W/ 50/60Hz /10A | 220V/1500W/ 50/60Hz /12A |

| Packing Dimension(mm) | 1620(L)X1100(W)X1110(H) | 1700(L)X1110(W)X1265(H) |

| Gross Weight | 380kg | 490kg |

Application

It is suitable for weighing candy, seeds, jelly, pet food, puffy

foods, pistachio, peanut, nuts, raisins, dried fruits, snack foods,

etc. (Tips : Do not suit for small granule and product with impact

force )

Adopting well-known Japanese and German brand load cells. Key components such as hoppers, linear pans, waterproof cover are made by high-precision molds, which contributes to high consistency and interchange-ability. The circuit board design adopts the industrial-grade design scheme, the industrial-grade material, and the manufacturing technology from the chip selection to the PCB design and the protection. The standard touch screens use an LCD screen of 50,000-hours-life, which adopts the immunity standard higher than the EC general standard industrial environment, and achieves a high-level design of 4kV.

Having a high-quality team with more than 30% professional technicians, which ensures our comprehensive capacity from R&D, manufacturing, marketing, installation, technical training to after-sales service for the complete automatic weighing packaging system.

|