| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Plastic Recycling Granulator Machine |

|---|---|

| Brand Name: | JIN MACHINE |

| Model Number: | JIN-75A |

| Certification: | CE Certificate |

| Place of Origin: | CHINA |

| MOQ: | 1 Set |

| Price: | Negotiable |

| Payment Terms: | T/T, L/C, D/A, D/P, Western Union, MoneyGram |

| Supply Ability: | 10 sets per month |

| Delivery Time: | 45 work days |

| Packaging Details: | Standard wooden frame and wooden case is available for Jin Machine Excellent Rigid Packaging drying dryer for plastic recycling |

| Application: | PET granulating |

| Material: | 304 Stainless Steel |

| Raw Material: | PET Flakes or bottles |

| Motor: | Siemens Brand |

| Warranty: | 12 Months |

| Production Period: | 55 Days |

| Capacity: | 100-800 kg/h |

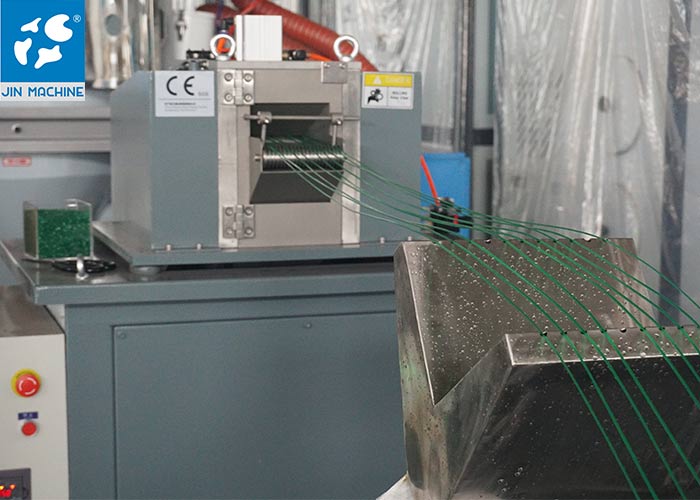

Plastic PET Granulating Machine 500kg / H PET Bottle Flakes Recycling

1. Introduction

We are Jin Machine, we are a modern family-owned enterprise. Which contains two mechanical manufacturing companies. Jinguan and Jinyue. Jinguan was established in 2006, focusing on mechanical design; Jinyue was established in 2017, focusing on research and development of drying and central conveying. Through 13 years of experience and technical accumulation, Jin Machine now offers a single machine or a complete set of centralized feeding, compounding, recycling and drying systems. We have excellent mechanical control, ultra-low energy consumption which is comparable to imported equipment. Besides, our fast after-sales response can let our customers get asuperb service experience.

PET granulator machine is good for reducing the plastic

degradation, granulating better pellets, which is really a good

choice for the customers in PET recycling.

Besides, this machine is easy to operate, and a very practical

granulation recycling model, it is very popular in the PET

recycling field.

3. Main Parameter

| NO. | Description of goods | Total Power Consumption | Quantity |

| 1 | Screw Feeder ( Convey to 3000L Drying Hooper) | 1.5 kw | 1 |

| 2 | CSG 3000 Dehumidifying Dryer | 96 kw | 1 |

| 3 | Screw Feeder (Convey to SJ100 Extruder) | 1.5 kw | 1 |

| 4 | SJ 120 Single Screw Extruder | 135 kw | 1 |

| 5 | Cooling bath | - | 1 |

| 6 | Air Dryer | 1.5 kw | 1 |

| 7 | Pelletizer | 5.5 kw | 1 |

| 8 | Vibrating Screen | 0.25 kw x 2 | 1 |

| 9 | Crystallizer | 35.5 kw | 1 |

| Total | 277 kw | ||

|