| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Non Woven Face Mask Making Machine |

|---|---|

| Place of Origin: | CHINA |

| Brand Name: | chuntai |

| Certification: | CE/ISO9001 |

| Supply Ability: | 20 set per month |

| Packaging Details: | wooden case |

| MOQ: | 1set |

| Price: | Negotiablet |

| Delivery Time: | 5 days |

| Payment Terms: | Negotiablet |

| Power(W): | 13KW |

| Dimension(L*W*H): | 5300MM*3300MM1700MM (Standard) |

| Voltage: | 220V AC;50HZ |

| Production Capacity: | 20/month |

| Key Selling Points: | High Capacity |

| Machine Weight: | 1500kgs |

| Machine Size: | 9500*1500*2200mm(including the Material Feeding Frame) |

| Required Environment: | humidity 5%-35% HR, Temperature 10-35 degree, no dust |

| Air Pressure: | 6Kg/c㎡ |

| Electric Specification: | 220V±5%, 50HZ |

| Capacity: | 150-180pcs / min |

Multiple Function Cupped Face Mask Machine Automatic Counting With Ultrasonic System

Product Description

Automatic Non Woven Mask Making Machine for Fighting the Coronavirus

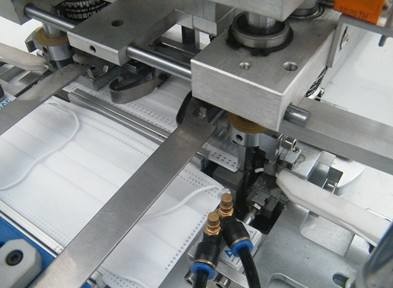

This machine uses ultrasounic to produce finished folding masks automatically. Including special optional function (Anti fog film welding and sponge nose wire welding, pringting) nose wire feeding, earloop welding, folding, forming and cutting, waste collected, the mask produce can be finished just in one machine. It only requires one worker to operate.

Technical Specifications

Basic Application | Applicable for Fully Automatic N95 Mask Machine with Ear Loop Welding Machine |

Machine Weight | 1500kgs |

Machine Size | 9500*1500*2200mm |

Required Environment | humidity 5%-35% HR, Temperature 10-35 degree, no dust, no flammable and corroded air |

Air Pressure | 6Kg/c㎡ |

Electric Specification | 220V±5%, 50HZ, single phase, 10kw |

Production Speed | 25-40 Pieces/min |

Frequency of Ultrasonic System | 15/20KHz |

Main Technical Features

● Designed with multiple functions, only one worker needed to

operate several production line easily, labor saving!

● Using high quality ultrasonic system,equipped with PLC screen

touch operation table,easy and convenient for

operating,stableperformance and high efficiency,don't destroy the

raw material.

● High automatically, from feeding raw material to collecting

finished products completed once time,high efficiency.

● Special feeding device with sensitive sensor,can feed raw

material without mistake. Fast and smoothly, reducing waste.

● Automatic counting,the production quantity can be settled.

Production Line Layout

1. Automatic funciton of nonwoven feeding, nose bridge inserting,

pattern welding, ear loop welding, mask fabric forming & folding

and mask shape cutting.

2. Adopting advanced brand components in pneumatic parts and

electric parts, which ensure machine performace.

3. Mask shape can be customized per client's sample.

4. Simple structure in linear type ,easy in installation and

maintainance.

5. Machine stable performance and constant operation is available

with over 99% qualified mask output.

|