| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Flexo Printer Slotter Die Cutter |

|---|---|

| Brand Name: | Xinglong |

| Model Number: | QYKMA2600 |

| Certification: | CE certificate |

| Place of Origin: | Hebei China |

| MOQ: | 1 set |

| Price: | Negotiation |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 100 set/Year |

| Delivery Time: | 40~50days |

| Packaging Details: | no package by FCL, wooden pallets and wooden case by LCL |

| After-sales Service Provided: | Engineers available to service machinery overseas |

| Warranty: | 1 Year |

| Machine inside width (mm): | 2600 |

| Max feeding paper size(mm): | 1200*2400 |

| Max effective printing size(mm): | 1200*2200 |

| Min coverage size(mm): | 430*700mm |

| Min slotting space(mm): | 260*90*260*90 |

| Working speed(pcs/min): | 70-130pcs/min |

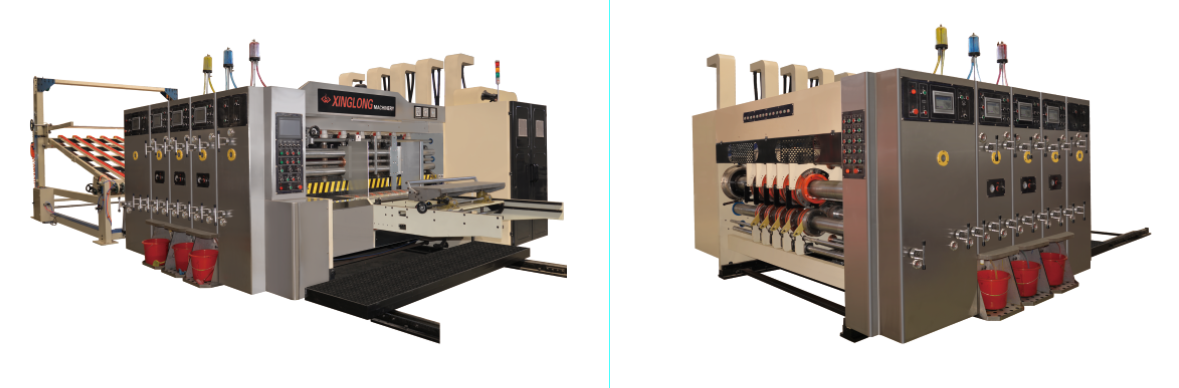

Mulit Colors High Speed Automatic Printing Slotting Machine With Stacker

Main Technology parameters

| Model | QYKMA410-2600 |

| Machine inside width (mm) | 2600 |

| Max feeding paper size(mm) | 1200*2400 |

| Max effective printing size(mm) | 1200*2200 |

| Min coverage size(mm) | 430*700mm |

| Min slotting space(mm) | 260*90*260*90 |

| Design speed(pcs/min) | 150pcs/min |

| Working speed(pcs/min) | 70-130pcs/min |

| Standard Thickness of printing plate | 6mm |

| Printing precision | ±0.75mm |

| Thickness of cardboard | 1.2-9mm |

| Wall thickness | 50mm |

| Main motor power | About 18kw |

Performance and Characteristics:

| No | Item | Function and configuration |

| 1 | Machine unit move |

|

| 2 | Roller type lead edge feeder |

|

| 3 | Feeding roller |

|

| 5 | Baffles |

|

| 6 | Dust-extraction unit | l Cleaning brush sweep board surface, improve the effect of printing |

| 7 | Automatic zero device |

|

2. Printing unit

| No | Item | Function and configuration |

| 1 | The printing roller |

|

| 2 | Impression roller |

|

| 3 | Suction box |

|

| 4 | Inked system |

|

| 6 | Phase adjustment |

|

| 8 | Printing phase fixed device |

|

| 9 | Zero-return and memory |

|

| 10 | Each unit Equipped with scaleplate |

|

3. Varnish unit

| No | Item | Function and configuration |

| 1 | The printing roller |

|

| 2 | Impression roller |

|

| 3 | Feeding roller |

|

| 4 | Anilox roller |

|

| 5 | Rubber roller |

|

| 6 | Phase adjustment |

|

| 7 | Ink supply system |

|

| 8 | Printing phase fixed device |

|

| 9 | Zero-return and memory |

|

| 10 | Each unit Equipped with scaleplate |

|

4 Slotting unit

| 1 | Board Catching table |

|

| 2 | Table lift-down |

|

| 3 | Baffle |

|

| 4 | Stack height |

|

|