| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Cemented Carbide Rods |

|---|---|

| Brand Name: | zhenfang |

| Model Number: | ZF-TCP028 |

| Certification: | ISO9001:2015 |

| Place of Origin: | Zhuzhou,China |

| MOQ: | 5KGS |

| Price: | Negotiable |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union |

| Supply Ability: | 10 tons per month |

| Delivery Time: | 3-15 days |

| Packaging Details: | standard packing suitable for overseas shipment: outside carton or plywood case with inner plastic box packing |

| Application: | Plunger pump |

| Products Name: | tungsten carbide plunger |

| Size: | Dia15*277, Dia20*277mm OEM accepted |

| Grade: | K10, K20,K30 YL10.2 |

| Grain Size: | 0.8μm |

| Material: | 100% virgin tungsten carbide |

| Hardness: | HRA92.5 |

| Service: | OEM ODM |

| Advantage: | high wear resistace |

| length: | customized |

| Shape: | round |

| Type: | power tool parts |

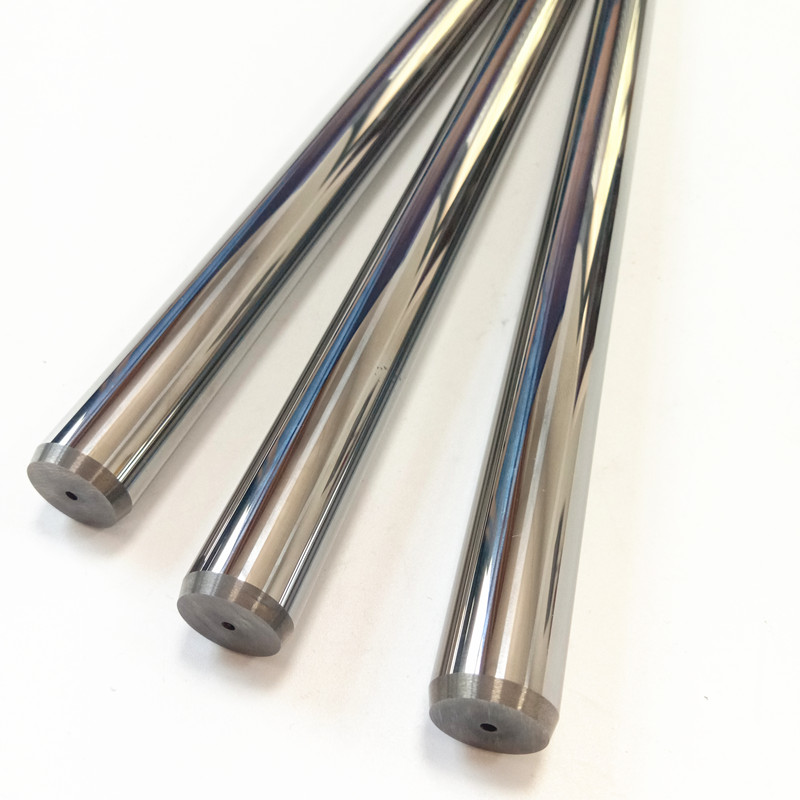

Corrosion-resistant Cemented Carbide Plunger For High Pressure Compressor Dia17*270mm

Our cemented carbide plungers are used at petrochemical plants in

the production of low-density polyethylene (LDPE) and ethylene

vinyl acetate (EVA).

These plungers function as pistons in high-pressure compressors,

where they are required to have high compressive strength, wear

resistance, and erosion resistance.

Application

- Components (pistons) for high-pressure compressors

- High-pressure plunger pumps

These products are used under high pressures, so there is concern that surface defects might lead to serious accidents. Applying a mirror finish to the surface makes defects easier to spot. Another benefit is that the plungers slide better within their packing.

Detail Information

1. Material: WC+Ni/WC+Co

All technical data only for reference. We can make based on requirement

Grade Information for plunger

Our advantage:

1. Material: using high quality raw material

2. Production Procedure: Powder preparing- Pressing-HIP sintering-

Processing-Finishing

3. Perfect quality control systerm: ISO9001:2015

4. Various dimension for choosing

5. Various grade for choosing based on your application. the

hardness is from HRA82 to HRA92.5

6. We also accept manufacturing based on your drawing

|