| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Silo Forming Machine |

|---|---|

| Brand Name: | ZBR |

| Model Number: | ZBR-S-1078 |

| Certification: | CE ISO |

| Place of Origin: | Jiangsu |

| MOQ: | 1 SET |

| Price: | Negotiated |

| Payment Terms: | Negotiated |

| Supply Ability: | 10 sets per month |

| Delivery Time: | 30 days |

| Packaging Details: | export package |

| After-Sale Service: | Lifetime |

| Material Width: | Up to 1500mm |

| Working Temperature: | -10--+60°C |

| Shaft Diameter: | Up to 120mm |

| Life Span: | 20 years |

| Rollers: | GCr15 |

Galvanized Steel Silo Forming Machine GCr15 Rollers With 18 Forming Stations

I. Galvanized Steel Silo Roll Forming Machine With 18 Forming Stations -- Widely Used

1. Material shape (storage): granular material, powder material, liquid material.

2. Industry: grain, feedstuff, Brewing, medicine, food, cement, etc.

3.Varieties in detail (storage): wheat, soybean, maize, sorghum wheat flour, bulk cement, fly ash, sewage, water, chemical syrup, etc.

4. Ordinary black steel sheets, galvanized steel sheets,high strength steel sheets, stainless steel sheets, aluminum alloy sheets.

II. Galvanized Steel Silo Roll Forming Machine With 18 Forming Stations -- Configuration

10 Tons decoiler(manual or hydraulic) -- 1 unit

Roll forming machine -- 1 unit

Punching system -- 2 units

Cutting system -- 1 unit

PLC control -- 1 unit

Hydraulic station -- 1 unit

Runout table or 6M auto stacker -- 1 unit

Spare tools -- one box

III. Galvanized Steel Silo Roll Forming Machine With 18 Forming Stations -- Working Process

Decoiler (10T Manual or Hydraulic) -- Guided Feeding -- Leveling -- Roll Forming -- Punching -- Arching -- Cutting -- Collection Table

IV. Galvanized Steel Silo Roll Forming Machine With 18 Forming Stations -- Main Parameters

| Suitable Raw Material | Galvanized sheet, Zinc aluminum sheet |

| Material’s Thickness | 1.2-4.5mm |

| Forming Stations | 18 |

| Maximum Feeding Width | 1250mm |

| Diameter of Roller’s Shaft | 120mm |

| Producing Speed | 4-8m/min |

| Material of Roller | GCr15 quenching HRC 58-62° |

| Drive Mode | Gear Box |

| Main Power | about 180KW |

| Electrical Control System | PLC Frequency Control |

| Dimension(L*W*H) | 35m*4.5m*4.5m |

| Total Weight | approx 70T |

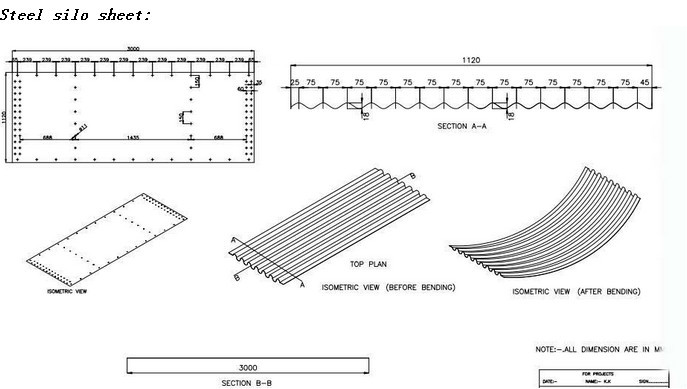

V. Galvanized Steel Silo Roll Forming Machine With 18 Forming Stations -- Popular Profile

FAQ

1). Does one machine can only produce one style panel profile?

Not exactly.For wider and double layer making machine. It can

produce more than 6 kinds of panels.

Besides, the width is adjustable.

2). Do you have after sales support?

Yes, we are happy to give advice and we also have skilled

technicians available across the world. We need your machines

running in order to keep your business running.

3). How to visit your company?

Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao

to Wuxi Station (30 minutes), then we can pick up you.

4). What can you do if the machine broken?

Our machines' warranty period is 12 months, if the broken parts

can't repair, we will send the new parts replace the broken parts

for free, but you need pay the express cost If after warranty

period, we can through negotiation to solve the problems, and we

supply the technical support for the whole life of the machine.

5). Can you be responsible for transport?

Yes, please tell me the destination port or address. we have rich

experience in transportation.

6). You are trade company or factory?

We are factories.

7). Why your price is higher than others?

As we persist on that factory should put quality at the first

place. We spend time and money on developing how to make machines

much more automatic, accurate and high quality. We can make sure

that our machine could use more than 20 years without any problem.

8). How long the machine could be made?

Normally speaking, deck floor roll forming machine could be made

about 60 working days. If you need machines in a hurry, we can try

it short time.

Rollers

|