| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Alumina Ceramic Plate |

|---|---|

| Brand Name: | Mingrui |

| Model Number: | XF- 478 |

| Certification: | ISO9001, , CE, UL, TUV |

| Place of Origin: | China |

| MOQ: | 1 pieces |

| Price: | negotiable |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram, D/P, D/A |

| Supply Ability: | 8000 pieces month |

| Delivery Time: | 15 working days after the order confirmed |

| Packaging Details: | intertional carton box |

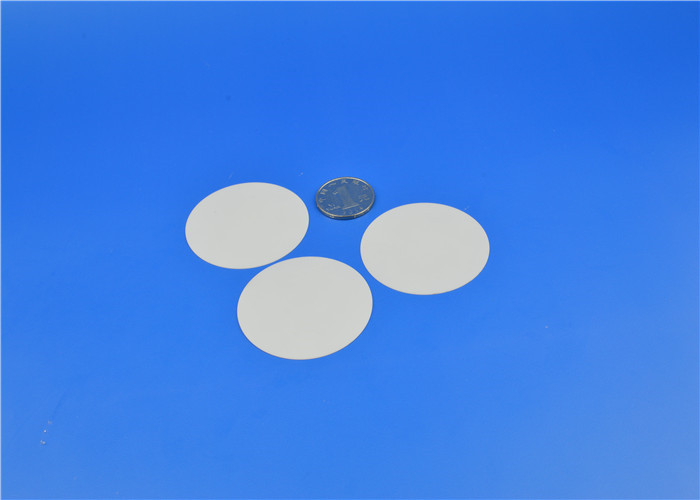

| Name: | Alumina Ceramic Piece |

| Application: | Medical device |

| Material: | alumina |

| Dimension: | 100 *50 * 0.25 mm or custom |

| Thickness: | 0.2mm |

| MOQ: | 1PCS |

| Shipping: | DHL EMS UPS FEDEX TNT |

| Type: | thin ceramic substrate |

| Features: | very thin |

| Delivery: | 10 days |

Advanced Alumina Ceramic Piece / Substrate / Sheets for Medical Device

Key words: Alumina Ceramic Piece

Application:

Alumina ceramic is mainly used in large power equipment, IC MOS

tube, IGBT chip heat conducting insulation, high frequency power

supply, communication, mechanical equipment, strong current, high

voltage, high temperature and other thermal heat insulation parts

need products.

Physical properties: high thermal conductivity, high voltage

insulation resistance, high temperature resistant, abrasion

resistant, high strength.

■Good smoothness / flatness with less porosity. Excellent in

adhesion with thin film and thick film materials.

■Less variance in outline, plate thickness, slit pitch, etc.

■Minimal warpage, bending, and undulation.

■Physical and chemical properties are stable even under a hot

environment. Excellent in thermal shock resistance. High thermal

conductivity and coefficient of thermal expansion similar to that

of silicon.

■Superior mechanical strength. Products with higher mechanical

strength are also in our lineup.

■Excellent resistance against oil and chemical.

■Excellent in insulation properties, high dielectric breakdown

voltage, high surface resistivity / volume resistivity, and small

dielectric constant.

■Stable breaking strength, and less variance in shape or

dimensions.

■The high reflective substrate, especially suitable for optical

applications such as LED, is also available.

Description of Alumina Ceramic Piece :

Alumina substrates can withstand high temperature and maintain high

strength and hardness. Alumina plates also have superb performances

in electrical insulation, high chemical resistance and low thermal

expansion. We have various sizes of semi finished shapes in stock

and are able to conduct custom manufacturing for all kinds of

alumina components.

Refractory alumina ceramic substrate/ceramic plate is our main product.Misson can supply high quality alumina plates with competitive prices.

Very small and very large sized plates can be made.

Fine grinding can made tight tolerance.

High temperature and abrasive resistance is good

Quality assurance:

Alumina ceramic is the most mature of the engineering ceramics, offering excellent electrical insulation properties together with high hardness and good wear resistance,but relatively low strength and fracture toughness.Alumina ceramics are generally white but may also be pink or ivory.The color is derived from either the sintering additives or impurities in the raw materials.

| Properties | Units | 95 Alumina | 99 Alumina | ZrO2 |

| Density | g / cm³ | 3.65 | 3.92 | 5.95-6.0g/cm³ |

| Water absorption | % | 0 | 0 | 0 |

| Coefficient of thermal expansion | 10-6/K | 7.9 | 8.5 | 10.5 |

| Modulus of Elasticity Young's Mod | GPa | 280 | 340 | 210 |

| Poisson's ratio | / | 0.21 | 0.22 | 0.3 |

| HV Hardness HV | MPa | 1400 | 1650 | 1300-1365 |

| Flexural Strength @ room temperature | MPa | 280 | 310 | 950 |

| Flexural Strength @700°C | MPa | 220 | 230 | 210 |

| Compressive Strength @ room temperature | MPa | 2000 | 2200 | 2000 |

| Fracture Toughness | MPa *m 1/2 | 3.8 | 4.2 | 10 |

| Heat conductivity @ room temperature | W/ m*k | 18-25 | 26-30 | 2-2.2 |

| Electrical Resistivity @ room temperature | Ω*mm2 /m | >1015 | >1016 | >1015 |

| Max use temperature | °C | 1500 | 1750 | 1050 |

| Resistance to acid alkaline | / | high | high | high |

| Dielectric Constant | / | 9.5 | 9.8 | 26 |

| Dielectric Strength | KV/mm | 16 | 22 | / |

| Thermol Shock Resistance | △ T ( °C ) | 220 | 180-200 | 280-350 |

| Tensile Strength @ 25 °C | MPa | 200 | 248 | 252 |

1. What kind of industry ceramics do you have ?

We specialized in 95% 97% 99% alumina ceramic and zirconia ceramic parts .

2. What kind of molding method do can you supply ?

Dry Pressing , isostatic pressing , grouting , hot-chamber die casting , tape casting , injection molding, etc, injection molding and isostatic molding is the most commonly used.

3.What stabilizer do you use when processing ?

Yttria stabilizer is the most commonly used in our industrial ceramic parts.

4.Can you produce free samples for me ?

Yes usually , we can produce free samples for you but it is up to the product complexity .

5.What terms can you accept for payment ?

T/T, L/C , Western union , Money Gram and Paypal is welcome , but paypal and western union only for small -sum payment.

|