| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Roller Shutter Door Machine |

|---|---|

| Model Number: | shutter door |

| Certification: | CE |

| MOQ: | 1 set |

| Payment Terms: | T/T, L/C, Western Union |

| Supply Ability: | 20 sets per month |

| Delivery Time: | Shipped in 30 days after payment |

| Packaging Details: | 1.Main body is nude 2. PLC, pump, shafts are covered with plastic film 3. Spare parts in carton box 4. Packed according to customer's request |

| Dimension(L*W*H):: | 6500*800*1200 |

| Weight:: | 3 ton |

| Driving Motor:: | 5.5kw |

| Production Capacity:: | 15-20m/min |

| Raw Material thickness:: | 0.3-0.6mm |

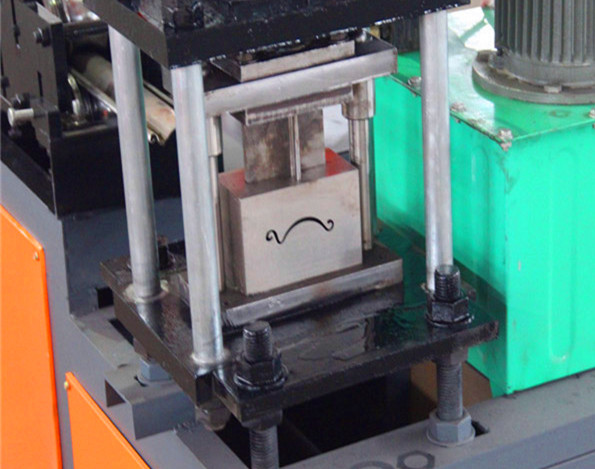

| Roller material:: | Cr12 Steel Quenched |

| Shaft material:: | High grade 45# steel,forged and quenched |

| After-sales Service Provided:: | Engineers available to service machinery overseas |

| Company Info. |

| RFM Cold Rolling Forming Machinery |

| Verified Supplier |

| View Contact Details |

| Product List |

3.5kW --12.5Kw Cold Roller Shutter Door Roll Forming Making Machine

1.

Metal Shutter Door Roll Forming Machine,Roofing Sheet Roll Forming Machine

The color steel sheet is widely used in villa , holiday village , gardening industrial building , storage , scenic tourist area , pavilions , hotel , exhibition hall and so on . And we are emphasis on the detail and the technical update constantly.

2.

Metal Shutter Door Roll Forming Machine,Roofing Sheet Roll Forming MachineComponents:

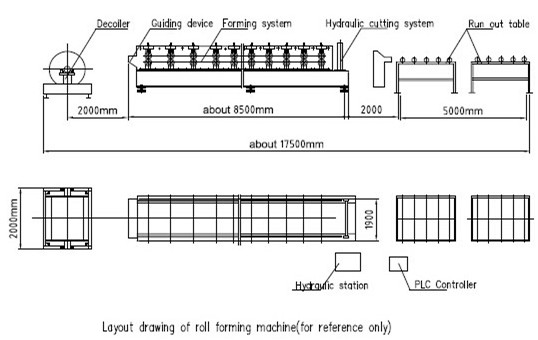

Uncoiler, Coil sheet guiding device, Main roll forming system,Post cutting device,Hydraulic station, PLC control system and Support table.

3. Shutter Door Roll Forming Machine Working Flow:

manual uncoiler—Roll forming machine—computer control system—hydraulic control system—form cutter

4. Technical Parameter

| No. | main parameter of Shutter Door Roll Forming Machine | |

| 1 | Suitable to process | Galvanized Steel |

| 2 | Width of the plate | 100mm |

| 3 | Rollers | 12stations |

| 4 | Dimensions | 3.5M*0.8M*1.2M |

| 5 | Power | 3KW |

| 6 | Thickness of the plate | 0.8-1.2mm |

| 7 | Productivity | 8-10m/min |

| 8 | Diameter of the roller | Φ50mm |

| 9 | Weight | About 2T |

| 10 | Voltage | 380V 50Hz 3phases |

| 11 | Material of the cutting plate | Cr12 |

| 12 | Hydraulic | 40# |

| 13 | Processing precision | Within 1.00mm |

| 14 | Control system | PLC control |

|