| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Wireless Charging Coil |

|---|---|

| Brand Name: | uchi |

| Model Number: | WX5010-6R3K08L |

| Certification: | UL ROH |

| Place of Origin: | Made in Dongguan |

| MOQ: | 10000 |

| Price: | USD |

| Payment Terms: | Western Union, MoneyGram, T/T |

| Supply Ability: | 10000000 |

| Packaging Details: | box( L350*W350*H170) |

| Core: | PC95 5.0*1.0 |

| Wire: | 0.08*105P*10.5TS |

| Sn: | sn99.3% |

| Cu: | 0.7% |

| Temp: | 25 degree |

| Humidity: | 70% |

| Yellow adhesive: | 1603 |

| tape maroon: | mylar tape |

| Company Info. |

| Guangdong Uchi Electronics Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Notching L wireless charging coils assembly WX5010-6R3K08L for

smart tv or phone and notebook

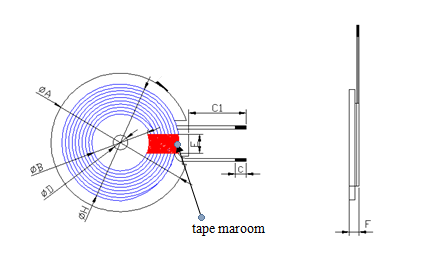

1. DIMENSIONS(MM)

| A(mm) | 50.0+/-1.0 |

| B (mm) | 20.5+/-0.5 |

| C(mm) | 1.5~3.0 |

| C1(mm) | 8.0+/-2.0 |

| E(mm) | 8.0Ref |

| F(mm) | 2.7Max |

| H(mm) | 43+/-1.0 |

| E(mm) | 8.0Ref |

2. MATERIAL:

a. CORE:PC95*1.0 notching "L"

b. WIRE:∮0.08*105P*12.5TS

c. Sn:Sn99.3% Cu:0.7%

d. Yellow adhesive:1603

e. tape maroon mylar tape (8.0mm width)

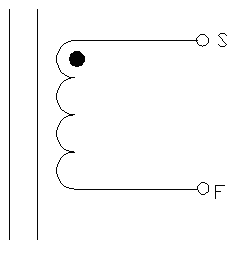

3.ELECTRICAL DIAGRAM:

4. ELECTRICAL CHAR ACTERISTIC:

| ITEM | SPEC | TEST EQUIPMENT | TEST CONDITION |

| L | 6.3uH+10% | WK5237 OR EQU | 100KHz/0.25V |

| DCR | 60(mΩ)MAX | 502BC | |

| Q Value) | 70 Min | WK5237 OR EQU | 100KHz/0.25V |

5. SPECIFICATION NO:

WX 5010 -6R3 K 08L |

6. TEST DATA:

| ELECTRICAL CHARACTERISTIC | ||||

| ITEM | L(μH) | DCR(mΩ) | Q | |

| SPEC | 6.3+/-10% | 60MAX | 70 Min | |

| 1 | 6.58 | 36.2 | 99.7 | |

| 2 | 6.54 | 36.1 | 96.6 | |

| 3 | 6.54 | 35.6 | 98.5 | |

| 4 | 6.51 | 36 | 98.6 | |

| 5 | 6.47 | 37 | 98.9 | |

| X | 6.528 | 36.18 | 98.46 | |

| R | 0.11 | 1.4 | 3.1 | |

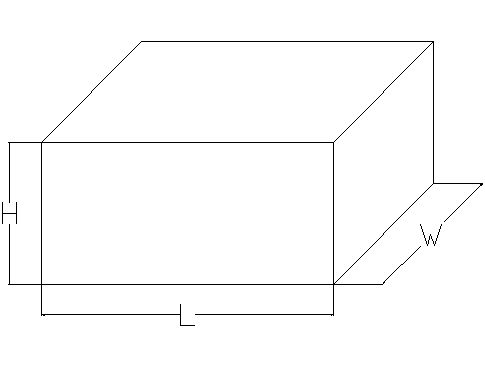

7.PACKAGING

a.quantity

b.packaing dimensions(mm)

| L | W | H |

| 350MAX | 350MAX | 170MAX |

8.RELIABILITY TEST

.1.STORAGE TEMPERATURE: | -40℃~85℃ |

.2.OPERATING TEMPERATURE RANGE : | -40℃~+85℃(CONTAIN HEATING COIL) -40℃~+85℃ |

3.EXTERNAL APPEARANCE : | NO EXTERNAL DEFECTS CAN BE FOUND IN THE VISUAL INSPECTION. |

4. TERMINAL STRENGTH : | FIXED INDUCTORS,ONE END OF THE ELECTRODE WITH 0.45KG PULLING FORCE,GUIDED THE NEEDLE DOES NOT FALL OFF. |

5.INSULATING RESISTANCE : | THE INSULATION RESISTANCE SHOULD BE OVER 1000MΩ WHEN D.C.100V IS APPLIED TO THE WINDING –CORE. MEANWHILE NO STRUCTURE AND ELECTRIC DEFECTS SHOULD BE FOUND FOR 1 MINUTE. |

6. HUMIDITY TEST : | INDUCTANCE DEVIATION IS WITHIN ±10.0% AND NO STRUCTURE AND ELECTRIC DEFECTS CAN BE FOUND AFTER 96±2hours TEST UNDER THE CONDITIONOF RELATIVE HUMIDITY OF 90~95% AND TEMPERATURE OF 40±5℃. AND 1 HOUR STORAGE UNDER ROOM AMBIENT CONDITIONS AFTER THE DEVICE IS WIPED WITH DRY CLOTH. |

7. VIBRATION TEST : | INDUCTANCE DEVIATION IS WITHIN ±10.0% AFTER 1 HOUR SWEEPING VIBRATION IN EACH THREE DIRECTIONS. NAMELY, FREQUENCY IS10~55Hz ANDTHE AMPLITUDE OF 1MINUTE CYCLE IS 1.5mm . |

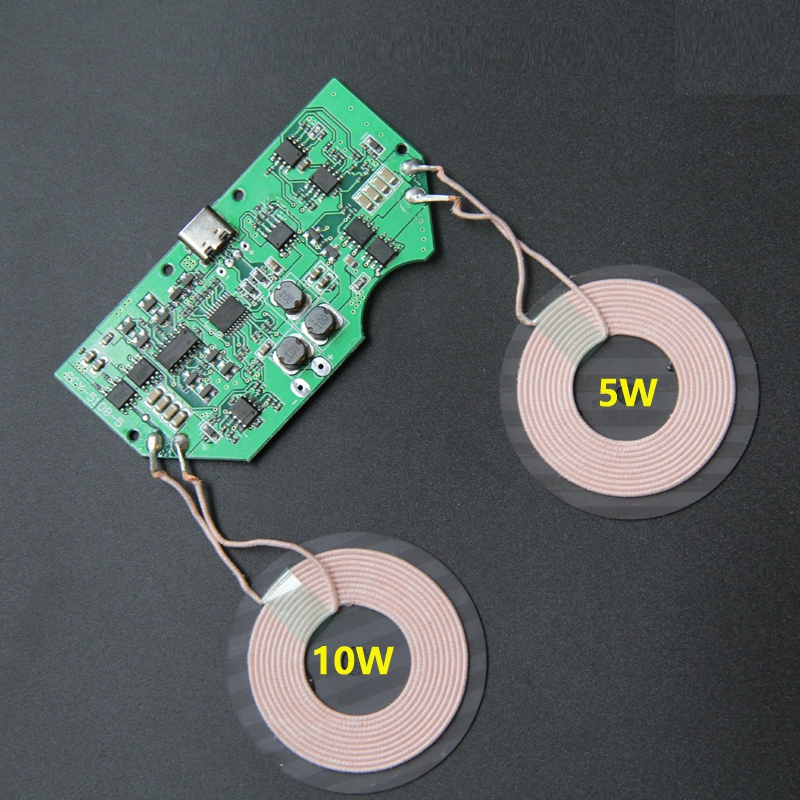

9.Background

Inductive Coupling: good coupling between two coils, a transmitter coil and a receiver coil. An alternating current in the transmitter coil generates a magnetic field which induces a voltage in the receiver coil. This voltage can be used to power a mobile device or charge a battery. It is ideal for wireless charging transmitter coil assembly and increase the charging efficiency.

10.Features

Wireless charging transmitter coil assembly (Tx - coil)

Litz wire winding Shield by Ni-Zn ferrite material

Compliance with Qi standard of WPC

11.Applications

Mobile Phones

Battery or battery Chargers

Cameras

MP3 /PMP

MID's

Hand Held Devices

Gaming devices

|