| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Steel Sheet Roll Forming Machine |

|---|---|

| Model Number: | floor decking Machine |

| Certification: | CE |

| MOQ: | 1 set |

| Price: | on discuss |

| Payment Terms: | T/T, L/C, Western Union |

| Supply Ability: | 20 sets per month |

| Delivery Time: | 30 days after receiving deposit |

| Packaging Details: | the Packaging Detail of roll forming machine door : Standard and safe export package, suitable for long term sea way shipping Delivery Detail: within 45 working days after down payment received |

| Model NO.:: | EN-130JK |

| Material Thickness:: | 0.4-0.7mm |

| Rolling Speed:: | 6-15m/Min |

| Roller Stations:: | 14 Stations |

| Hydraulic Cutting Power:: | 5.5kw |

| Material of Shaft:: | 45 Steel |

| Transport Package:: | Plastic Film, Container |

| HS Code:: | 845522100 |

| Company Info. |

| RFM Cold Rolling Forming Machinery |

| Verified Supplier |

| View Contact Details |

| Product List |

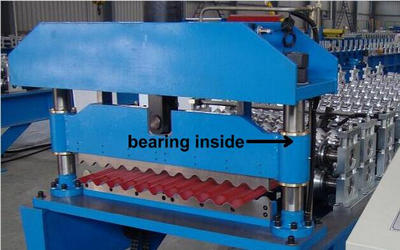

Automatic Roofing Sheet Roll Forming Machine Double Layer Corrugated For Building

Machine components

| No. | Name | Qty |

| 1. | De-coiler | 1 Set |

| 2. | Roll Forming Machine | 1 Set |

| 3. | Hydraulic Cutting Device | 1 Set |

| 4. | PLC Control Box | 1 Set |

| 5. | Hydraulic Pump | 1 Set |

| 6. | Output table | 1 Set |

Decoiler

| Type | Manual type(standard) | Hydraulic type(option) |

| Photo |  |  |

| Width | 1250mm | 1500mm |

| Capacity | Max 5tons | From 5-15 tons |

| Inner diameter | φ508-610mm | φ508-610mm |

| Outer diameter | φ1500mm | φ1800mm |

roll forming

| Item | Parameter detail | ||||||||

| Processing Material | GI and PPGI | ||||||||

| Material thickness | 0.25-0.8mm | ||||||||

| Machine frame | 360#H steel, Adopt diagonal line welding, leveling instrument measurement to make sure the final frame is high-precision | ||||||||

| Machine siding panel |

| ||||||||

| Forming stations | 13-22 stations(according to the profiles) | ||||||||

| Machine rollers | high grade No.45 forged steel,plated hard chroming with thickness

0.05mm Processing way:cutting--drilling--CNC lathing--quenching--CNC lathing--chroming | ||||||||

| Machine Shaft | φ70-80mm high garde No.45 steel after treatment, | ||||||||

| Machine spacers | CNC lathing in high-precision | ||||||||

| Machine bearings | China Haerbin bearing or SKF international bearing(option) | ||||||||

| Driving system | 1 inch chain or gear box(option) | ||||||||

| Machine power | 3kw-11kw(according to the profiles) | ||||||||

| Machine working speed | 8-12m/min or 10-30m/min(option) | ||||||||

| Machine adjust type | After machine installation, we will test it ourselves, compare with the profile drawing, the difference is controlled in 0.5mm |

Cutting

| Type | bearing sliding type |

| Blade material | Cr12mov quenching and grinding |

| Frame processing | the whole bottom frame is grinding for high-precision |

| Blade processing | wire-electrode cutting, but the upper balde can not be straight. this is technology |

| Working | Hydraulic type |

Stacker

| Type | Manual | Auto(option)  |

| Length | 1.5m-2m | 6m or 12m |

PLC

| Main item | Parameter detail |

| PLC | Delta(standard) or according to your request  |

| Inverter | China brand(standard) or according to your request |

| Touch screen | Mcgs(standard) or according to your request |

| Encoder | China brand(standard) or according to your request |

| Voltage/HZ/Phase | 380v/50-60hz/3phase |

|