| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Micro Temperature Sensor |

|---|---|

| Brand Name: | Aolittel |

| Model Number: | CWFB0104FC-301C12a |

| MOQ: | 1000 Pieces |

| Price: | USD 0.8 to 1 Per Pieces |

| Payment Terms: | T/T |

| Supply Ability: | 1,000,000 Pieces Per Month |

| Delivery Time: | 2-4 Weeks |

| Packaging Details: | Bulk,1000pcs/6kg |

| Type: | Induction Cooker Temperature Sensor |

| R25: | 100KΩ±1% |

| B25/50: | 3950±1% |

| Housing: | Brass 2×0.3mm , Φ28×18.5 Silica Gel (Brown) |

| Casing: | Φ2 L=15mm Heat shrinkable casing (Black) |

| Cable: | L=300mm AWG26 200℃ Fluorine plastic wire (Black) |

| Company Info. |

| Aolittel Technology Co.,Ltd |

| View Contact Details |

| Product List |

Home Replacing Induction Cooker Glass NTC Thermistors Micro Temperature Sensor 100K 3950 With 2 Pin Wired 300mm

Application: The sensor is installed on metallic surface for temperature detection, and the sensor is mostly installed in induction cooker, induction heating cooktop, and heat sink of kitchen appliances.

__________________________________________________________________________ Download________

Download________

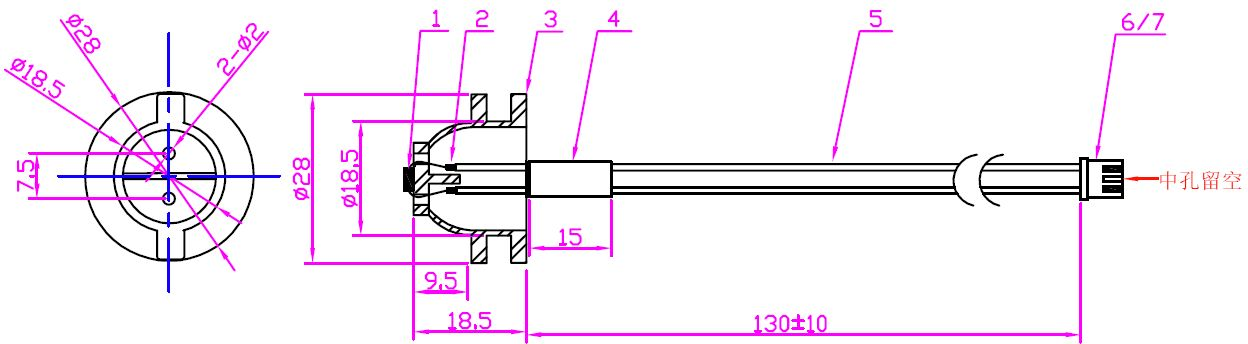

Size (mm)

Components

| NO. | Name | Description |

| 1 | Thermistor | R25=100KΩ±1% B25/50=3950±1% |

| 2 | Housing | Brass 2×0.3mm , Φ28×18.5 Silica Gel (Brown) |

| 3 | Casing | Φ2 L=15mm Heat shrinkable casing (Black) |

| 4 | Cable | L=300mm AWG26 200℃ Fluorine plastic wire (Black) |

| 5 | Connector | XH-2Y/ XH-2.54(White) |

Performances Requirements

| Resistance at 25℃ | 100KΩ±1% |

| B25/50 | 3950±1% |

| Dissipation Factor | 2.5mW/C |

| Thermal Time constant | 10 sec |

| Operating temp.range | -40~+250C |

| Insulation resistance | 100MOhm at 500VDC |

| Withstand voltage test | 10 sec at 1500VAC |

Actual Product Photos

Package

Bulk, 1000pcs per box,6kg/box.

How does an induction cooktop measure temperature?

Induction cookers use NTC Thermistor temperature sensors, more

specifically thermocouples to measure temperature.

But for 60 deg. C, I don’t think it can be much useful, because the

thermocouple cannot measure such precise temperature (it measures

only in 100s from 100–2000) like you said.

If you have a thermometer, insert it in the cooktop and make sure

thermometer bulb is immersed in liquid to be boiled. Keep a close

watch on the thermometer all the time. On and off the induction

continuously to maintain 60 deg. C in the cooktop.

Reliability

| NO | Item | Technical requirements | Test conditions and method |

| 5-1. | High temp. Test | DR/R25£±3% DB/B£±3% No change with withstand voltage, Insalution performance. Appearance without damage. | 100±5℃,power on 500±24 hrs,DC0.2mA |

| 5-2. | Low temp. tes | -20±5℃,power on 500±24 hrs,DC0.2mA | |

| 5-3. | Endure moisture test | Store in environment 55±2℃,90%-95%RH for 500±24 hrs | |

| 5-4. | Temp. cycle test | –20℃×30min→Room temp.×10min→ in 100℃ water×30min→Room temp.×10min 10 cycles | |

| 5-5 | Load electrify test | Power on DC1mA, 500hrs in room temp. and humid. | |

| 5-6 | Drop test | Free fall into concrete floor from height 1M ,10 cycle. | |

| 5-7 | Vibration test | Frequency range:10~55HZ Total amplitude 1.52mm 1 cycle 1 min ,direction and time X,Y,Z axs 2Hr each. | |

| 5-8 | Bending test | Bend 180°binding site wire and epoxy resin.Back and forth 10 times |

|