| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | H Beam Production Line |

|---|---|

| Brand Name: | Luole |

| Model Number: | LFJ-5 |

| Certification: | CE/ISO |

| Place of Origin: | WUXI |

| MOQ: | 1 |

| Price: | 14,000USD |

| Payment Terms: | T/T |

| Supply Ability: | 10 sets / month |

| Delivery Time: | 20-25 days |

| Packaging Details: | Plastic Bubbles |

| Tilting Angle:: | ±360° |

| Capacity: | 5 Tons |

| 2500mm (Two Columns Center Distance): | 2500 mm |

| Lifting Speed: | 1500 mm |

| Chain Model: | 24B Heavy Duty |

| Motor Power: | 4 x 1.5 kw |

| Company Info. |

| Wuxi Luole Machinery Co., Ltd |

| View Contact Details |

| Product List |

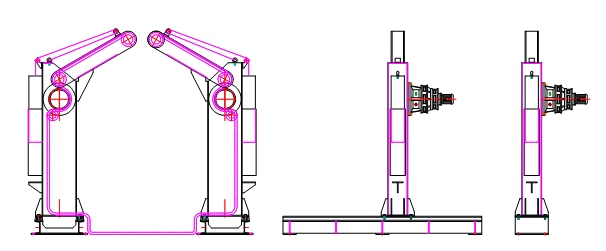

360° Overturning I Beam Rotator 4x1.5 KW Motors Loading Capacity 5 Tons Tanks Rotator

Equipment usage

1. This machine is designed to change position of heavy products by flipping when welding. It provide higher efficiency and safer work area.

2. Widely used on I beam tilting , out-of-shape tank turning etc..

Detail introduction

1. The flipping tires work on turning products in 360 degree so as to adjust the position of the product.The equipment structure is like upside down gantry type. It has four reducer to control the product piece and

very convenient to apply when flipping.

2. The flipping tires are consist of swing arm, pillar and reset device, electric control and operating

system. It also includes four standing columns attached with driving mechanism on each top. The brake

motor controls the cycloidal pinwheel reducer to drive the sprockets.

3. The chain wheel is equipped with two pulley, the pulley installed on the swing arm.On the role of the

pulley is change the movement direction of the chain and chain extension. There is a guide wheel close to the bottom of the chain wheel , that use for increasing the angle on the sprocket chain.

4. By using the post box welded structure, with enough stiffness and strength, the four standing columns

are capable of using a long period with outstanding stability.

5. There are a swing arm and a heavy hammer device on the standing columns. When the work piece

need to flip, the swing arm goes downward with a certain angle. If there is no need to flip over the work

piece, the swing arm is raised, and the chain is loosen, to make the work piece either delivered neatly.

6. The flipping tires have lifting chain to rotate the work piece, so as to solve the problem of work piece

turn slippy. There are four reducers can turn direction, either same-directional or reverse rotation.

Same-directional rotation is to flip artifact,and reverse rotation is to lift artifacts.

7. To reach the length requirement of work pieces, one side standing columns are designed fixed while

the other side of two columns respectively equipped with a sliding seat. Please fix both sides before use.

8. Control system includes: main control cabinet hand control box, hand control box with 15 meters cable connected to the control cabinet, hand control box can be used in different location of the equipment to operate equipment.

9. The manual operation box and master ark with buttons, such as power up, stop, reverse direction

selector switch and abrupt stop button.

10. Control system has motor over-current, over-voltage and over torque protection.

11. Control system is equipped with temperature detection device, stop and alarm when over-temperature.

12. Control system has simple and convenient operation, reliable operation. The operation can be close to control or remote control operation, and it is convenient to the operator at any location.

Technical Parameters

Model Item | LFJ-50 |

Load Capacity | 5T |

Left-right Column Center Distance | 2500mm |

Front-back Column Center Distance | (Depends on work piece length) |

Flipping Machine Motor Power | 1.5kw×4 |

Chain model | 24B heavy duty |

Flipping Angle | ±360° |

Lifting Speed | 1500mm/min(const-speed) |

Input Voltage | 3PH 380V/50Hz |

Quality Assurance and After-sales Service

1. Equipment installation and debugging is responsible by the supplier;Debugging tools, and personnel

required for coordination between the two parties to solve, installed base by the supplier to provide the

drawings, the buyer production.

2. The supplier can assist the buyer's operating personnel training.

3.The seller to the buyer service commitments: host warranty for a year, to provide door to door service,

warranty service according to the buyer's notification action within 24 hours, the buyer to assist.

4. Lifelong provide maintenance services and spare parts supply, after the warranty cost for wiring.

If you have any other special request,please just write me emial for discussion

|